EFFECTIVENESS

CONFIRMATION OF RESULTS

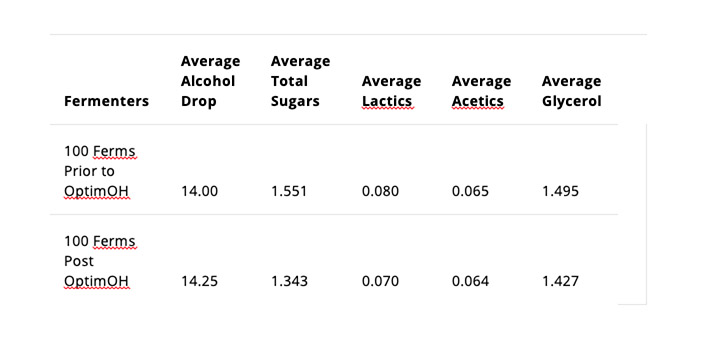

OptimOH has been subjected to intensive testing by Anitox scientists, the US National Corn to Ethanol Research Center (NCERC) and commercial partners. Validations have taken place in full-scale fermentations within ICM and Delta-T designed facilities.

Test results confirmed that OptimOH delivers:

- higher ethanol yield

- improved fermentation performance

- ability to eliminate use of antibiotics

- control of biofilms

- residue-free co-products

- suitability for fermentations running at various pH levels

INCORPORATING OPTIMOH

- OptimOH is applied up-front via a closed system, directly into the corn slurry. This inhibits biofilm formation in the mash lines, controlling the bacteria that competes with your sugar conversion

- OptimOH effectiveness does not degrade over time

- OptimOH is metabolised by the yeast during fermentation and does not affect the physical or nutritional quality of co-product and does not result in residue carry-over

- By reducing biofilm in lines, tanks and heat exchangers, OptimOH reduces ‘dead legs’ where bacteria can build up

- OptimOH can lower dependance on sulfuric acid used to artificially lower pH as a traditional means of bacteria control

- OptimOH generates no emissions in waste water or fermentation gas scrubbers

The decision to deploy OptimOH requires no modifications to your alcohol production process. Anitox installs a pre-designed application system that can be installed within the cook system, depending upon the design of the plant. To see how your plant could use OptimOH to control bacteria without the use of antibiotics – and increase alcohol yield – contact the Anitox Biofuels and Fermentation Program team.